The Roller Company provides a range of precision machined industrial roller crowning and grinding services to ensure you get the most out of your precision machined industrial rollers. This normal entryexit principle will be used later to help determine the path of a web through a machine.

The conveyor belts arc of contact on the drive drums is to be increased.

. Here is an example application of a crowned pulley and flat belts in a modern application. Neoprene Urethane Peek Nylon Steel Stainless Polyacetal. Crowned rollers have a slight curve invisible to the naked eye which helps them stay centered on surfaces that are slightly misaligned or not perfectly flat.

Even on troughed conveyors flat face and crowned pulleys are generally used. Crowning Data for Conveyor Belt Rollers. Crossed-roller linear guides are based on a non-recirculating linear bearing design in which cylindrical roller bearing elements are oriented in a crisscross pattern.

Mount the studded wheel into a threaded hole. Crowned pulleys and V-guiding are the two common methods of belt tracking and in the course of this article. There is not a need for pulleys to be crowned or tapered when a v-guide is used.

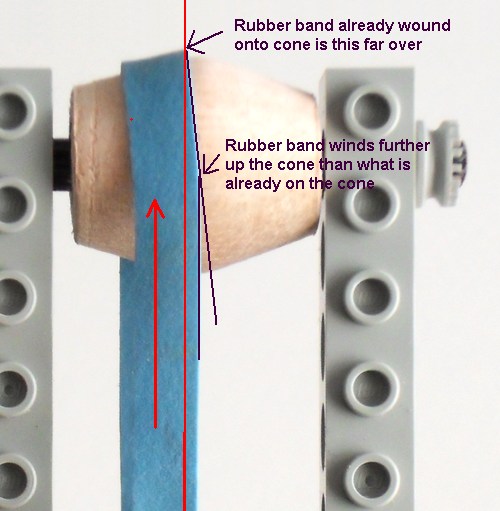

So your job is to figure out why this happens and explain it fully enough to account for the observed behavior. How crowned pulleys keep a flat belt tracking Before V-belts were invented machinery was usually powered through flat canvas belts running on crowned pulleys. Their main purpose is to accommodate misalignment of linear guide surfaces while providing smooth and quiet guided motion.

This collection leverages our patented. In this Design Guide the editors of Design World detail these considerations as well as the most common variations and applications of crossed-roller linear bearings. The web tracking over the larger diameters lanes will have increased strain and tension.

These flat belts stayed centered on pulleys without any guides or flanges. This study proposes an improved design method for roller guide. Dimensions for V-Guides and Grooves.

Crowning Data for Flat Belt Drives. However they are still rollers which are tricky to ride and have a learning curve. Crowning Data for Conveyor Belt Rollers.

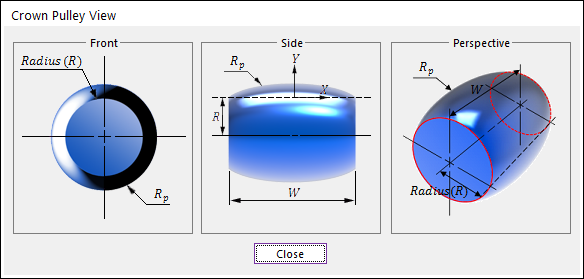

05313 to 409 inch. Geometry of crowned pulleys. Crowned rollers have resulted in greater load-carrying capability and longer bearing lifeCrowned rollers under load distribute stress equally along their full length of contact with the raceways thereby eliminating stress concentration at the roller ends.

This product line takes us back to our roots of solving everyday challenges for industries such as architecture transportation semiconductor electronics engineering services and many others. MadeWell crown rollers are linear guide bearings with integrated mounting stud and curved outside diameter. On pulleys with 24 face width some engineers prefer a convex crown pulley shape.

Snub rollers are used when. The influences of the rollers profile on stiffness stress distribution of roller linear guide are analyzed using finite element simulation. 138 to 1417 inch.

The V that is there first hit in a groove that runs the length to the pulleys and conveyor. The latest computerized grinding machines along with the basic beam principle roller specifications and the users operating load requirements are the factors leading to precision crowned rollers. A concave crown is seldom used unless there is a very special reason to do so.

The key to keeping them tracking centered on the pulleys is the use of crowned pulleys. Crowning Data for Flat Belt Drives. Crowned Roller Design Guide.

It seems plausible that the belt riding on the crown should be stable and a look at this picture helps. A crowned roller is a drive drum with a cylindrical center section with 2 tapered sections on each end. Concentric version is for mounting to a fixed location.

157 to 189 inch. Similarly the web will also tend to exit a roller in a normal direction. Operation in extreme temperature.

It should be noted however that specifi c applications specialized processes and goods that need. MadeWell represents simple solutions for complex problems. For technical drawings and 3-D models click on a part number.

Cylindrical-conical or radially crowned shaped pulleys or other appropriate tracking measures mentioned in this guide. Dimensions for V-Guides and Grooves. The design recommendations in this Engineering Guide have been found to be successful as a general rule in practice.

Guidelines for amount of Roller Crown H mm H mm Roller Diameter mm Less than 200mm 200mm to 500mm Greater than 500mm 1 Ply Belting 05 08 10 2 Ply Belting 07 13 15 3 Ply Belting 10 16 20 This method uses the tapered sections of the roller to steer the running conveyor belt to the center of the roller. Not only governs spreading but also describes web behavior at misaligned rollers guides and winders. Crowned profi les Solid lubricants Double-fl ange rollers Consult Osborn with special features or requirements not listed.

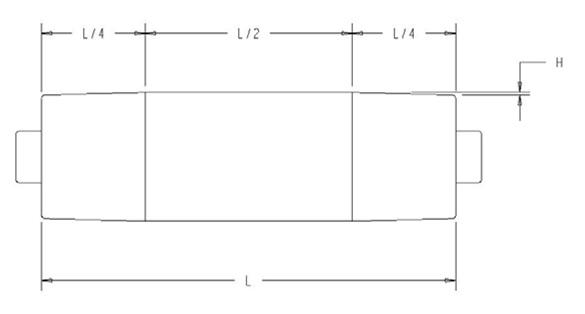

Operation in Severe Environments Temperature Extremes Standard Load Runners idler-rollers are designed to operate in temperatures ranging from -30 F to 225 F -34 C to 107 C. For example in the design of spherical parallel manipulators 25 in the design of crowned cylindrical roller bearings 13 estimation in. Is the crown height of the cylindrical-conical or radially crowned pulleys.

In this work the design of the roller slider and the overall structure is. The length of the tapered section is generally ½ the length of the cylindrical center section. If the arc of contact of snub rollers sup - port and guide rollers is small the dia-meters of these rollers may equal 12 d.

Including styles such as Cylindrical Convex Crown Straight Taper with Center Flat Straight Taper Concave Crown and more. Adjustment is still recommended to tune in the crowned roller due to compensating for production tolerances of the conveyor and the belt. Guide rollers are preferable to lateral wear strips in this respect.

Roll and Rock Cowgirl 499384 Top. This seems counter-intuitive at first. Flat Crowned And Radial.

Ad Cam yolk track guide rollers bearings. Rollers with seal have an end seal to protect the rolling elements from dirt and contamination. Dimensions for V-Guides and Grooves.

We will discuss the pros and cons of each method separately. If you are looking for a training solution that is simple and foolproof a rear wheel trainer or spin bike may be more suited for your needs. A crowned pulley eliminates the need for pulley flanges and belt guide rollers.

The distance between the top and return side must be small for design or construction reasons. MadeWell Radial Wheels Crown Rollers. Genetic algorithms are also used in other kind of study.

Crowning Data for Conveyor Belt Rollers. Crown Rollers are the most stable rollers on the market and are significantly easier to ride than any other set of rollers. Checklist regarding design issues in order to avoid tracking problems.

The shape of a crown is nominally the shape of a beam deflected under a uniformly distributed load as shown in Figure 3. There is a plastic that adheres to the back of the V-guided belts.

Crowning Data For Conveyor Belt Rollers Splawn Belting

![]()

3 Basic Conveyor Belt Tracking Rules To Follow Accurate Industrial

Crowned Pulleys Which Option Is Right For You Sparks Belting

Belt Conveyor Tracking V Guided Vs Crowned Roller Dorner Conveyors

0 comments

Post a Comment